The engraved portion (effigy) of stamps printed from the new Swiss Wifag press in 1951 were soon observed to be some 0.4 – 0.5 mm shorter than those previously printed using the old US made Stickney press. Notwithstanding the different perforation (now 11½ x 11½ rather than 14 x 13½), we shall examine why this should have been so.

fig 1. Comparison between Stickney and Wifag printed stamp heights

The pitch of the whole stamp altered rather less than this, as there is more paper round the new design to maintain stamp size with the changed perforation. From perforation considerations and the number of perforation recesses (r) (see Emission Poortman de 1936 (1) page 175) we have for the 10 Fr stamps from my enlarged photoscans:

| mm | r | perf | |

| Stickney printing stamp length ≈ | 20 x | 19 ÷ | 13½ = 28.1 mm |

| Wifag printing stamp length ≈ | 20 x | 16 ÷ | 11½ = 27.8 mm |

Again this will vary due to paper moisture and resultant shrinkage on drying. Wifag have told me that the paper was used dry for their press, ie there was no wetting as for the Stickney.

E & M Deneumostier (1, p175) quoted an article by Eric Mesdagh, which first appeared in La Revue Info-Phila du Philaclub Flemalle No 73-1 of 2000, in which Mesdagh theorised that a new Poortman profile was created in 1951 for the Wifag press. He goes on to say that it was remarkable that a smaller master die was employed for the new stamps. The real question remained that since Maurice Poortman had retired 1942, who engraved the new master die, which still bore Poortman’s name? The 11 Fr stamp issued in 1983 upon Leopold’s death again used the same master die engraved by Poortman as for 1951, but with the value added by Jean De Vos (2, p222). Mesdagh asserts the whole die was re-engraved by De Vos. This is incorrect and not what is stated in the Catalogue Officiel.

You will notice that the width of the stamps from both presses remained nearly constant.

The composite photo (fig 4) shows beyond any doubt that the same master die was used to produce stamps from both presses. A 10 Fr stamp from each press was superimposed and used to produce this. Differential enlarging to get the register was used as stamp widths vary too. The clarity of engraving in the face, especially, could not have been separately engraved and still be coincident. The fine lines are just not reproducible. Remember that engraving was entirely manual.

Furthermore, during the forming (bending) of the Stickney plates, engraved lines along the curvature will be stretched relative to those across the stamps. No deformation occurs on the Wifag press due to the direct transfer. If different master dies had been used for each press, the composite photo would not show the very good correlation, which it does. My thanks go to Note Printing Australia for producing this important comparator photo.

Let us now examine the differences between the two presses, which gave this apparently unexpected result, but which is entirely logical.

First, I wish to examine the Wifag press, as its operation is quite straightforward. The transfer wheel (molette) transfers several images from the master die onto its cylindrical surface to make up the platens. Once the impressions have been transferred from the master die to the transfer wheel, the latter is hardened. This is standard process for all presses. In this case 4 platens of 50 impressions each were formed on the cylinder. This method produces the same size image on the platen as that of the master die. Subsequent hardening and hard chrome plating (HCP) essentially leave the size unaltered. The master die is a negative (in reverse), the transfer wheel positive and the platen again negative, so the final stamp is positive. This process again is common to both presses.

The Stickney press was manufactured in two sizes, 9¼” (235 mm) and 13″ (584 mm) diameter printing cylinders. To determine which belonged to l’Atelier du Timbre, let us examine the resultant sheets printed.

Poortman sheets had 15 stamps high by 10 wide thus producing 300 stamps in 2 sheets per revolution of the cylinder. With each stamp 28mm high, as we calculated above, a sheet extends 420 mm excluding the selvedge edges. This equates to 16.5″ (≈ 420 mm) arc around the cylinder.

A 9¼” diameter cylinder has a half perimeter of 14½” (368 mm), which is too short for the stamps being printed. With the 13″ diameter cylinder, the half perimeter = 20½” (518 mm), which gives adequate space for selvedge edges and hold down for the platens. Thus they owned the larger type press. (Whether 300 or 600 stamps were printed in one revolution is immaterial, since the other 300 would have been along the axis and not have altered the cylinder diameter. The space was available.)

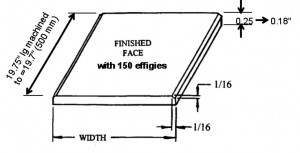

This time the transfer wheel transferred images onto a flat steel plate 0.25″ thick (6.4 mm), which was 19.75″ long (502 mm). The flat plate (platen) was then chamfered along the side edges and trimmed and squared up, probably ending up ≈ 19.65″ (500) long. The back was also machined parallel to the front and 0.18″ thick (4.57 mm).

fig 2. Diagrammatic view of flat plate after images have been transferred by the molette

Next the platen was formed into a semi circle to go round the cylinder, two platens thus forming the circle. The platen OD became 13″. Now when you form metal thus, the inside diameter cannot shrink or you get puckering. Thus the outside diameter (OD) must stretch, and it was this, which primarily caused the disparity in printed sizes of the stamps between presses. As we shall see, the whole platen was elongated, even the ID slightly.

fig 3. Diagrammatic view showing formed semi-circular plates

| equiv | stretch | |||

| Half perimeter for platen ID | = ½π x (13 – 0.36) | = 19.85” | (504 mm) | ≈ 4 mm |

| Half perimeter for platen OD | = ½π x 13 | = 20.42” | (518 mm) | ≈18 mm |

OD stretch ≈ 18/500 mm = 3.6%, which for a 25mm high image amounts to 0.9 mm. This made each platen image nearly 1mm longer than the original master die height.

From direct measurement on stamps, I found the following (see fig 5 for details):

| spread | mean | ||

| Stickney press stamps had effigy heights of | 24.7-25.1 mm | 0.4 mm | 24.96 |

| Wifag press stamps had effigy heights of | 24.4-24.6 mm | 0.2 mm | 24.47 |

| Thus, the mean difference between printings is | 0.49 mm |

Widths averaged 20.9 mm off the Stickney and 21.0 mm from the Wifag presses

Examination of measurements initially for the 4 Fr stamps showed two dies. Both are perforated 11½, yet the blue was printed on the Stickney press and the ultramarine from the Wifag. That is clear from the Catalogue Officiel. The 6 Fr (type I at least – I do not possess any type II) would seem to have been printed on the Stickney press. The effigy heights correspond with Stickney dies, while the widths are slightly more akin to Wifag printings. Maybe somebody, more knowledgeable than I, can explain this apparent anomaly.

We may draw the following conclusions:

- The Stickney effigy die size, as used after forming etc, was around 0.9 mm longer than the master die height – but the Wifag die remained the same as the master die height.

- The overall stamp height was ≈ 0.3 mm longer printed from the Stickney press compared with the Wifag press

- The height of the printed effigy averaged 0.49 mm longer from the Stickney press compared with that from the Wifag (see 6 Fr possible anomaly)

- As a result, about half of the platen stretch from forming was negated by the additional paper shrinkage of the Stickney press compared with that from the Wifag. But it still remained consistently longer.

Thus, nobody engraved a new master die for the Wifag press. The same Poortman master engraving was used for all printings, although who engraved the values as required in 1950-1951 may be unknown (Janssens, De Bast ?). Certainly De Vos added the values for the 11 Fr in 1983.

My special thanks go to Louis Repeta for his help with various aspects of the Stickney press, including two other articles, which he had written and kindly sent me. Also I wish to thank Cecelia Wertheimer (BEP, Washington) for much information she sent me about Benjamin Stickney and his press and Wilson Hulme at the Smithsonian Institution (Washington) for putting me in touch with Louis Repeta.

References.

- L’Emission Poortman de 1936, E & M Deneumostier, Belgium, 2001

- Catalogue Officiel de Timbres-Poste Belgique, CPBNTP, Belgium 2002

- Monograph, The Stickney Rotary Printing Press, Louis E. Repeta, USA

fig 4. Composite photo produced using 1936 (Stickney) & 1951 (Wifag) 10 Fr stamps,

which clearly shows the same master die was used to produce both platens

See correlation in the face particularly

fig 5. Poortman stamp effigy measurements (outside of frame)

Addendum

After publication of my original research findings (Belgapost Vol 20 pp 8-12 of March 2007), I sent a copy of the article to Mr Jan Wauters. He was the previous Printing Works Manager at the stamp printery in Malines – Mechelen known as l’Atelier du Timbre or Zegeldrukkerij depending on your French – Flemish preferences.

I first met Mr Wauters during his visit to Melbourne ’99 stamp exhibition and later that year, when I visited Malines. While he was not at the printery during the Stickney press era, he was conversant with the process.

I sent him a copy for both his information and comments concerning the apparent measured height of the 6 Fr carmine-rose (type 1) p11½ stamps. These were longer than other stamps printed on the Wifag and more closely matched Stickney press printed stamps (see table on p 12 of the original article). From measurements of stamps I possessed, the average height was 24.8 mm rather than 24.5 mm from the Wifag press. Admittedly these were early days for the Wifag press and the printers, as well as the press, were ‘bedding in’.

Mr Wauters, in a nice letter of reply, said that the 6 Fr stamps had been printed on the Wifag press and offered three reasons as to why they were over length. You will recall from my article and reference 2 that the two 4 Fr stamps (blue = Stickney, ultramarine = Wifag) were well documented.

- Paper quality could vary, some papers being more elastic than others and so stretch more (Lower modulus of elasticity).

- (Here he differed about info I had received previously from Wifag, the latter saying the paper was used dry) The paper was moistened a bit by the gravure cylinder, affecting paper stretch. That was possible because the last wiping cloth, which was in contact with the cylinder, could be moistened and it could be too wet to wipe the cylinder before printing.

- The gravure cylinder on the Wifag press could be warmed by means of an electric resistance. If the printers did not pay attention, it could happen that the cylinder became too warm, so that the circumference was slightly larger – this to dry the paper.

Discussion

- Assuming a mean effigy length of 24.50 mm on the Wifag for stamps other than the 6 Fr, image difference = 0.3 mm.

- With a linear coefficient of ≈ 1.12 x 10-5 / oC for steel, a 150oC temperature rise only causes 0.0002 mm increase. Essentially, we can forget temperature effects.

- Thus proffered reasons 1 & 2 must combine to produce the bulk of the effect observed. Also, If the paper is being run nearly dry, it may well be that the paper tension is higher on the Wifag than the Stickney press. Also, a higher temperature will cause wetted paper to stretch more easily. Was the paper suitable for the Stickney but not the Wifag press? We may only guess. Thus we can probably conclude there was an aberration caused by unfamiliarity with the new press and how best to control and use it. I would dearly like to be able to measure some 6 Fr type 2 stamps to see if the trouble persisted, since the same die retouched was used. May I borrow a dozen examples from somebody, please?

My thanks to Jan Wauters for his knowledge, interest and help in trying to solve the 6 Fr die 1 stamp length anomaly.

Leave A Comment

You must be logged in to post a comment.